Blown Film Extrusion Machine

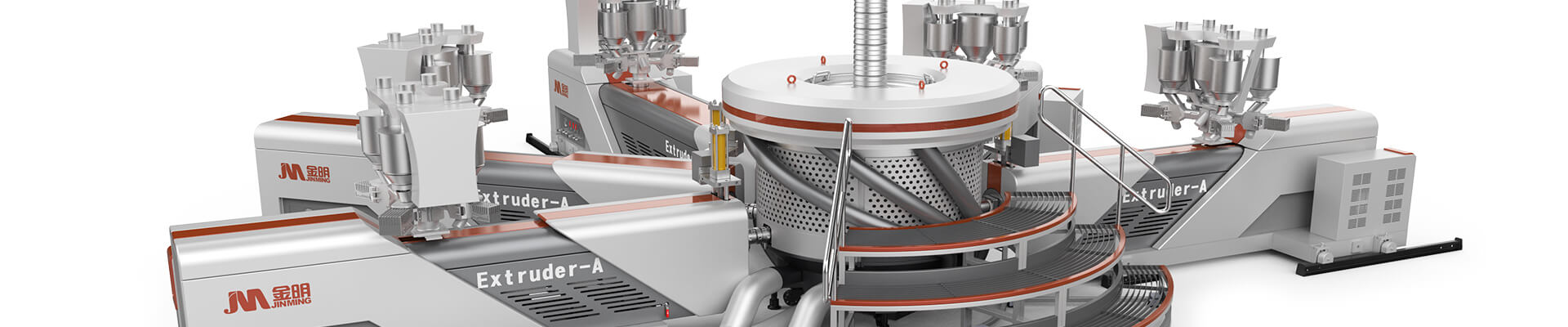

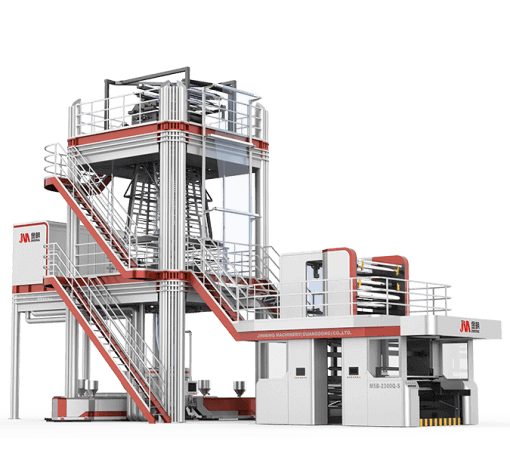

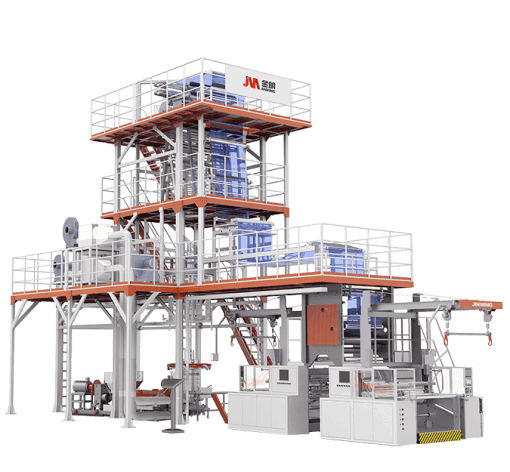

The Blown Film Extrusion Machine is widely used in food and commodity packaging, agriculture, and industrial applications. It encompasses various processes such as air cooling, water quenching, and multi-bubble forming processing, supporting up to 11 layers of co-extrusion. The die diameter can reach up to 3600mm. The extrusion, cooling, rotating haul-off system, machine direction orientation stretching unit, and fully automated configuration are all independently developed by Jinming, ensuring uniform thickness, high flatness, and excellent winding quality of the products.

The three major product series are tailored to customer needs, combining high production capacity, low energy consumption, and superior product quality to fully meet diversified production requirements.

-

Blown Film Extrusion Line (Air-cooling)

3, 5 Layer Co-extrusion Blown Non-barrier Stretch Film Machine 5 to 11 Layer Blown High-barrier Film Extrusion Machine -

Blown Film Extrusion Line (Water-quenching)

5 to 11 Layer Blown High-barrier Film Extrusion Machine -

Multi-bubble Blown Film Extrusion Line

5 to 11 Layer Blown Dual-bubble Shrink Film (POF) Extrusion Machine

-

Blown Film Extrusion Line (Air-cooling)

3, 5 Layer Blown Extrusion Non-barrier Stretch Film Machine 5 to 11 Layer Blown High-barrier Film Extrusion Machine 3 to 7 Layer Blown Agricultural Film Extrusion Machine 3, 4 Layer Co-extrusion Blown Geomembrane Film Machine 3, 5 Layer Blown FFS Heavy-duty Film Extrusion Machine 2, 3 Layer Blown TPU Breathable Film Extrusion Machine 3, 5 Layer Co-extrusion Blown PE Self-adhesive Protective Film Machine Blown PVDF Film Extrusion Machine -

Blown Film Extrusion Line (Water-quenching)

3, 5 Layer Blown Non-barrier Film Extrusion Machine 5 to 11 Layer Co-extrusion Blown High-barrier Film Machine -

Multi-bubble Blown Film Extrusion Line

3, 5 Layer Blown POF Shrink Film Extrusion Machine

-

Blown Film Extrusion Line (Air-cooling)

3, 5 Layer Co-extrusion Blown Non-barrier Mulching Film Machine 5, 7 Layer Blown High-barrier Film Extrusion Machine

JINMING's Blown Film Extrusion Machine Series

SupereX Series

The SupereX Series features high-performance blown film extrusion machines supporting 5 to 11-layer co-extrusion. Ideal for high-barrier film production used in food packaging, medical, and industrial sectors, these machines incorporate advanced die heads, vacuum sizing water rings, and modular winders to ensure consistent quality.

ClassicX Series

The ClassicX Series provides mid-range customized solutions with 3 to 7-layer co-extrusion capabilities. Designed specifically for agricultural films, heavy-duty packaging, and geomembranes, these machines include multi-flow air rings, inline printing units, and embossing and gusseting units for enhanced functionality.

ValueX Series

Our ValueX Series offers economical 3 to 5-layer blown film extrusion lines, perfect for non-barrier mulching films and general packaging applications. These machines feature high-precision components and advanced manufacturing processes to ensure reliable performance and film consistency.

Advanced Technology and Benefits

- Layer Flexibility: Supporting 3 to 11-layer configurations tailored to specific applications.

- Advanced Cooling Systems: Featuring air cooling, water quenching, and multi-bubble technologies.

- Automation and Control: Smart systems enable real-time monitoring and precise control.

- High Output Capacity: Production capacities of up to 78 tons/day, suited for large-scale manufacturing.