ClassicX Series

3, 5 Layer Blown Extrusion Non-barrier Stretch Film Machine

The M3B-1700Q-C is a cutting-edge 5-layer co-extruded blown film line specifically engineered for the production of superior quality non-barrier stretch films. Designed to cater to demanding industrial packaging requirements, this extrusion line consistently produces films that exhibit exceptional transparency, uniform thickness distribution, and remarkable mechanical properties. It is especially suitable for applications including stretch hood films, pallet wrap, heat shrinkable films, agricultural films, and high-grade food packaging films.

Leveraging advanced five-layer co-extrusion technology, the M3B-1700Q-C offers unparalleled flexibility in film formulation, allowing producers to customize layer properties for enhanced strength, puncture resistance, elasticity, and clarity. Its sophisticated control systems ensure precise thickness management and uniform melt distribution, significantly reducing material waste and production variability.

Key Technical Highlights:

- Advanced five-layer co-extrusion technology for optimal film strength, clarity, and layer uniformity.

- High-output capability designed for large-scale, industrial-grade film production, maximizing throughput efficiency.

- Precision thickness control system equipped with a reversing haul-off unit (rotating ±360°), ensuring minimal thickness variation and excellent film flatness.

- Robust internal bubble cooling (IBC) system to ensure consistent film cooling, improving production speed and stability.

- User-friendly centralized digital control panel provides real-time monitoring and fine-tuning of production parameters, ensuring consistently high product quality and operational efficiency.

- Versatile material compatibility including LLDPE, LDPE, mLLDPE, EVA, and other specialty polymers tailored for diverse market applications.

Application

Parts Introduction

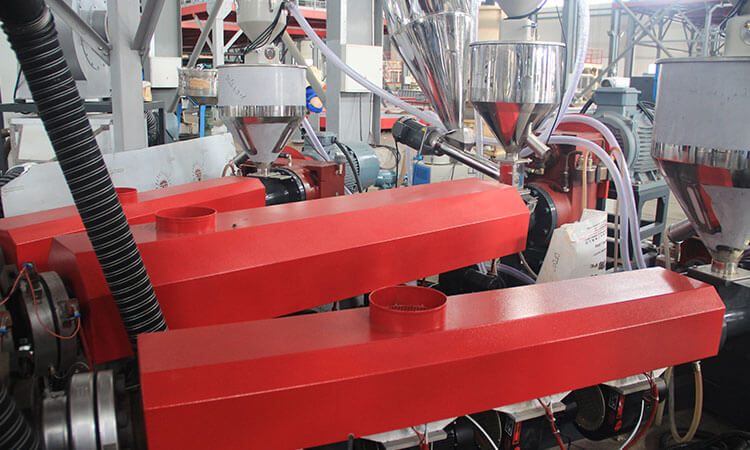

Extruder

Based on rich experience considering resin features and rheological principles, by continuous simulation and optimized designing, JM has launched various serials of extruding system for processing of different materials. The extruders with optimized designing are accurately processed, which not only have good corrosive and abrasive resistance performance, but also feature with high output capability, low energy consumption and great plasticization.

Reversing Haul-off Unit

The reversing haul-off unit is an advanced international technology, which is ±360°horizontally rotating, so that it can evenly draw the stretch film toward certain direction and decrease or eliminate its thick and thin points to ensure flatness winding and effectively avoid bump.

Electrical Control System

It is a centralized computer control system for the whole machine, which not only monitors processing parameters such as temperature, pressure, current, extruder running speed, water ring cooling system, machine line speed, and tension etc., but also displays the running recipes, layer ratio, output and thickness of each layer and total output etc. The system also has automatic warning and self-diagnosis functions.

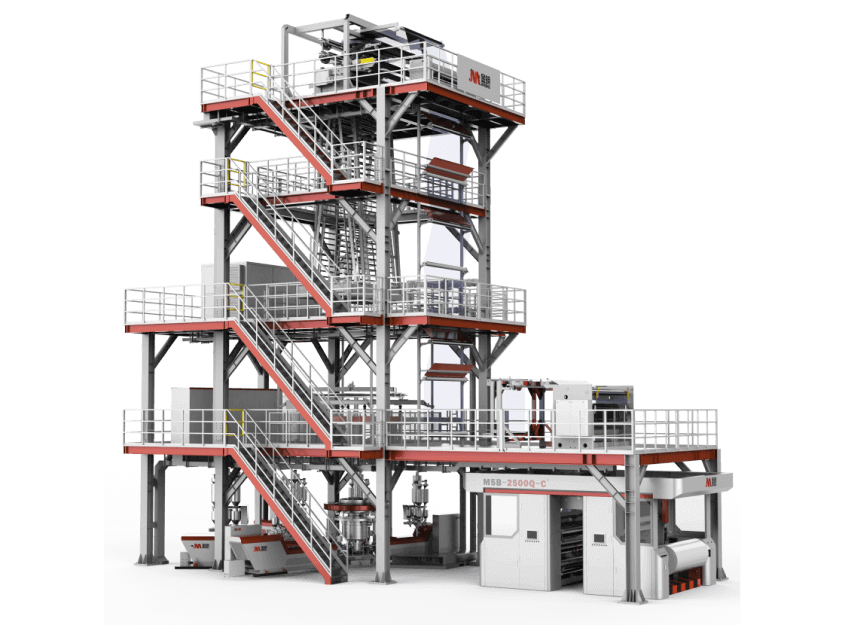

Equipment Exhibition

The 3-5 layers non-barrier stretch film extrusion machine display, including extruder, reversing haul-off unit, and electrical control system.

Technical Parameter

Please pull it to show more info

| Model |

|---|

| Multi Layer |

| Max. Stretch Film Width |

| Stretch Film Thickness Range |

| For processing of |

| Screw Diameter |

| Max. Extrusion throughput |

| Total Power |

| Max. Haul-off Speed |

| Dimension |

| 3 | 3 | 3 | 5 | 5 |

| 1600mm | 2100mm | 2500mm | 1600mm | 2300mm |

| 0.03-0.12mm | 0.03-0.12mm | 0.03-0.12mm | 0.03-0.15mm | 0.03-0.15mm |

| LDPE, LLDPE, mLLDPE, EVA, HDPE | LDPE, LLDPE, mLLDPE, EVA, HDPE | LDPE, LLDPE, mLLDPE, EVA, HDPE | LDPE, LLDPE, mLLDPE, EVA, HDPE | LDPE, LLDPE, mLLDPE, EVA, HDPE |

| Φ60/80/60mm | Φ70/105/70mm | Φ90/105/90mm | Φ60/60/70/60/60mm | Φ60/60/90/60/60mm |

| 560kg/H | 950kg/H | 1150kg/H | 760kg/H | 910kg/H |

| 390kw | 530kw | 690kw | 460kw | 530kw |

| 80-120m/min | 80-120m/min | 80-120m/min | 80-120m/min | 80-120m/min |

| 16.5×7.5×13m | 18.5×9.2×17m | 18.5×9.5×18m | 17×8.8×12.8m | 18×9.8×17.5m |

Other models such as M3B-1300-C,M3B-1500Q-C、M3B-2500Q-C、M5B-2300Q-C、M5B-3200Q-C and etc. would be also available.