Extrusion Lamination Machine

The Extrusion Lamination Machine serves material applications such as paper-plastic lamination, non-woven fabric lamination, and liquid packaging. It is compatible with a wide range of substrates, ensuring uniform coating that significantly enhances the product's durability and water resistance. The coating speed can reach up to 300m/min depending on customer requirements.

JINMING's Extrusion Lamination Machine Product Series

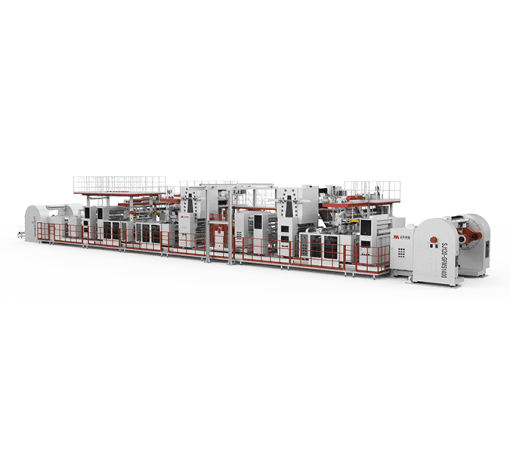

SupereX Series

The SupereX Series features high-speed extrusion lamination machines designed for demanding packaging applications. These systems support advanced resin compatibility and are equipped with microcomputer automation and color touch-screen interfaces for precise control. Ideal for producing laminated paper, film, or foil structures used in food, beverage, and consumer goods packaging.

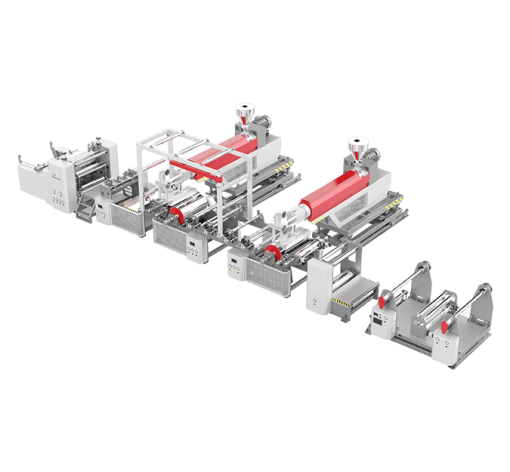

ClassicX Series

The ClassicX Series offers tandem extrusion coating and lamination machines tailored for textile and technical fabric applications. With stable output and advanced thickness control, these machines are suitable for products like rescue tents, dustproof cloths, and industrial packaging laminates.

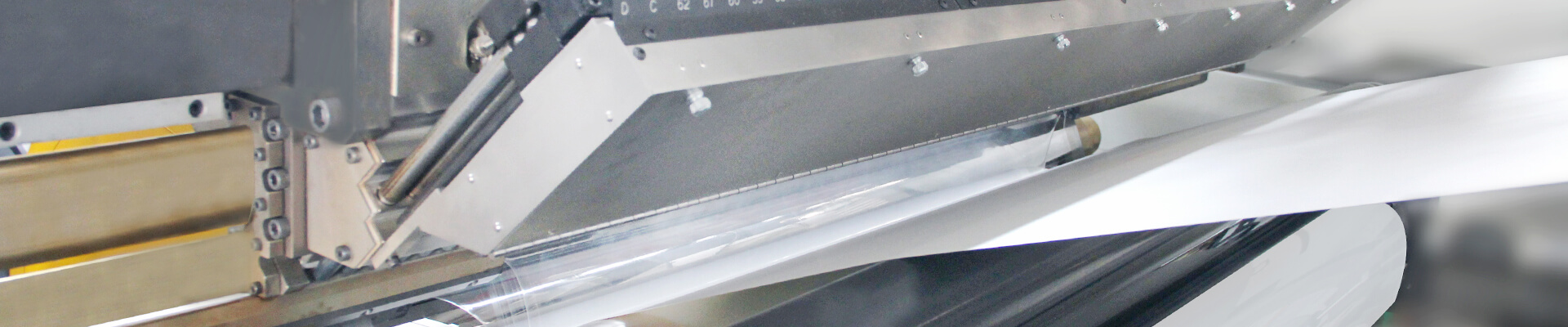

Technical Advantages

- High-Speed Coating: Achieve coating speeds up to 300m/min to meet high-volume demands.

- Advanced Control Systems: Equipped with Siemens or equivalent PLCs, real-time process monitoring, and user-friendly operation.

- Multi-Material Compatibility: Process various substrates including paper, woven/non-woven fabric, aluminum foil, and plastic films.

- Consistent Film Quality: Ensures even lamination thickness, strong adhesion, and high optical clarity.

Applications

- Flexible Packaging: Paper-laminated film for snack packaging, liquid pouches, or personal care goods.

- Industrial Textiles: Functional coatings for waterproof, breathable, or UV-resistant fabrics.

- Liquid Packaging: High-barrier laminated structures for milk, juice, or detergent packaging.