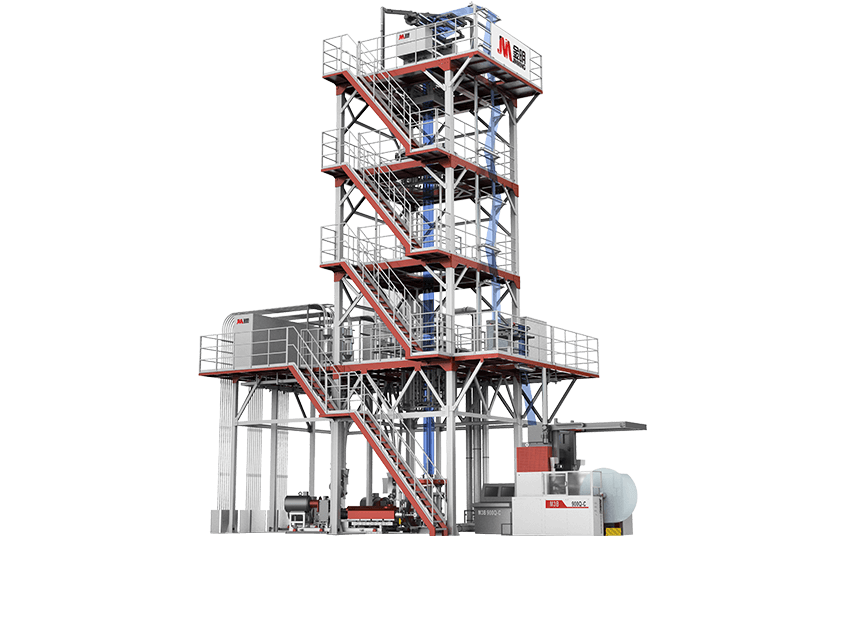

ClassicX Series

3, 5 Layer Blown FFS Heavy-duty Film Extrusion Machine

The M3B-900Q-C Heavy Duty FFS Film Extrusion Machine is specifically engineered to manufacture high-performance heavy duty FFS films. Utilizing advanced multi-layer blown film technology, this machine consistently delivers films with superior strength, uniform thickness, and excellent sealing properties. Designed for demanding industrial packaging applications, these films provide robust protection and efficient handling for bulk materials including fertilizers, chemicals, resins, and building materials.

With an optimized extrusion throughput of up to 560 kg/h, the M3B-900Q-C supports a wide range of materials such as LDPE, LLDPE, mLLDPE, HDPE, and POE. Its precision control system ensures consistent film quality and efficient production processes, making it the ideal solution for manufacturers seeking reliability and performance in heavy duty FFS film production.

Key Technical Highlights:

- Enhanced bubble stability system to increase output by 15–20%, enabling stable high-speed production.

- Secondary cooling ring below the collapsing frame to prevent tube blocking and ensure continuous film transport — even at high throughput levels.

- Multi-layer die head (3–5 layers) designed to optimize melt pressure and accommodate high-strength mono- and co-extruded film structures.

- Inline printing capabilities supporting up to 6-color printing, including gusset areas, for high visual impact.

- Optional micro-perforation unit available for powder-based packaging applications.

- Ideal for FFS films used in fertilizers, resins, and industrial powders — delivering high tensile strength and sealing reliability without requiring anti-block additives.

Application

Parts Introduction

Multi-flow Air Ring

Based on rich experience, Jinming develops this serial of liftable multiple air lip high efficiency air ring. It evenly controls air temperature by heaters to effectively control bubble horizontal thickness variation, meanwhile with the close-looped control of thickness profiler, film thickness will be automatically adjusted. It can not only improve film quality, but also enhance cooling efficiency so that increase output by approx. 30-50%. Besides, with the pre-cooling function before blowing up the bubble, it can improve film transparency and its mechanical performance. It is also applicable for processing of high blow-up ratio products.

In-line Printing Unit

The satellite type flexographic printer is applicable for precise printing with multiple colors. Each printing plate has short distance, which can shorten tinting time and reduce material consumption. It equips with automatic mixing and oil recycling system, so it can avoid color difference and improve printing speed.

In-line Embossing & Gusseting Unit

It equips with one set of dual-side and dual-row embossing unit. The gusseting unit is made of wooden boards, with depth manually adjustable.

Equipment Exhibition

The 3-5 layer FFS heavy-duty film extrusion machine display, including multi-flow air ring, in-line printing unit, and in-line embossing & gusseting unit.

Technical Parameter

| Model |

|---|

| Layer |

| Max. Film Width |

| Film Thickness Range |

| For processing of |

| Screw Diameter |

| Max. Extrusion throughput |

| Total Power |

| Max. Haul-off Speed |

| Dimension |

| 3 | 5 |

| 750mm | 750mm |

| 0.03-0.20mm | 0.03-0.20mm |

| LDPE, LLDPE, mLLDPE, HDPE, POE...etc | LDPE, LLDPE, mLLDPE, HDPE, POE...etc |

| Φ60/80/60mm | Φ60/70/80/70/60mm |

| 560kg/H | 970kg/H |

| 350kw | 600kw |

| 60m/min | 60m/min |

| 15×8×17m | 15×10×17m |

Other models such as M3B-1300Q-C、M5B-1300Q-C and etc. would be also available.