SupereX Series

5 to 11 Layer High-barrier Cast Film Extrusion Machine

SupereX high-barrier cast film extrusion machine line is Jinming's high-intellectualized and high-performance series with features of high-output, high-automatization and superior thickness deviation, etc.. Besides, SupereX has a good adaptability of resins, which meets customers' needs on high quality and high output.

Application

Parts Introduction

Extruders

Based on more than 30 years' designing experience, by velocity test for various processing materials, rheological simulation for screw, JM has developed a serial of low temperature extruding systems for processing of different materials, which can effectively decrease melt extruding temperature and shear rate. Therefore it is good for improving film physical performance and decrease unit energy consumption.

Feed Block & T-die

The feed block and T-die adopt floating layer designing with extrusion capacity is adjustable. They have short 3D melt channels without dead angle. It equips with single-material trim wrapping system, which will effectively reduce waste of trim from expensive materials. Through optimization of running parameters, it has solved technical problem of trim wrapping for PA, EVOH etc. materials.

Electrical Control System

It equips with Siemens centralized computer control system. Through PLC, it integrated control extruder temperature, transition unit, winder, trim collection unit and roll temperature etc. It uses imported Germany high precision temperature control. This system is easy for operation and displayable on touch screen, where parameters that can be set, changed or checked.

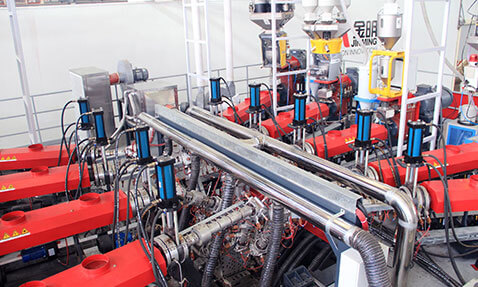

Equipment Exhibition

The 5-11 layers high-barrier cast film extrusion machine display, including extruders, feed block & T-die, and electrical control system.

Technical Parameter

| Model |

|---|

| Layer |

| Die lip size |

| Film width |

| Film thickness |

| For processing of |

| Line Speed |

| Max. Extrusion throughput |

| Total power |

| Dimension |

| 9 | 9 |

| 2500mm | 3000mm |

| 2100mm | 0.012~0.06mm |

| 0.03~0.25mm | 0.03~0.25mm |

| PP, PE, EVA, POE, PA, EVOH...etc | PP, PE, EVA, POE, PA, EVOH...etc |

| 150m/min | 150m/min |

| 830kg/H | 910kg/H |

| 850kVA | 950kVA |

| 24x11x8m | 25x12x8m |